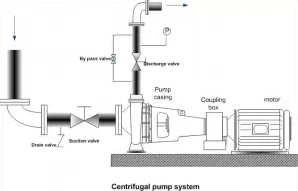

Why Discharge Valve Is Closed In Centrifugal Pump

why is it important to close the discharge valve before operating the centrifugal pump?

The reason why the discharge valve of a centrifugal pump should be closed before starting is to protect the motor, control flow, balance pipeline pressure, prevent backflow, control temperature, prevent idling, control noise, prevent gas from entering, protect the pipeline system and improve the efficiency of the pump. To ensure the safe and stable operation of the centrifugal pump in actual operation, we need to choose appropriate and correct operating methods. Next, we will elaborate on the following 10 points one by one.

1. Protect the motor: When the centrifugal pump is started, if the discharge valve is closed, the pump power is minimal, which can reduce the starting current, thus protecting the motor from being damaged by excessive current.

2. Control flow: When the discharge valve is closed, the flow can be controlled to prevent the centrifugal pump's head from being reduced due to excessive flow, thereby affecting the normal operation of the centrifugal pump.

3. Balance the pipeline pressure: Before opening the centrifugal pump, closing the discharge valve can balance the pipeline pressure. We need to open the centrifugal pump at a lower pressure to avoid damage to the centrifugal pump due to excessive pipeline pressure.

4. Prevent backflow: If the centrifugal pump is started without closing the discharge valve, backflow may occur, causing damage to the pump. Closing the discharge valve can avoid this backflow phenomenon.

5. Control the temperature: The centrifugal pump will generate heat during operation. Closing the discharge valve can control the temperature of the centrifugal pump to prevent damage to the centrifugal pump due to excessive temperature.

6. Prevent idling: If the centrifugal pump is started without water, idling may occur, which will cause damage to components such as the impeller and mechanical seal of the centrifugal pump. Closing the discharge valve prevents idling and protects the mechanical components of the centrifugal pump.

7. Control noise: When the centrifugal pump is started, if the discharge valve is not closed, loud noise may be produced, affecting the working environment and the health of operators. Closing the discharge valve can effectively control noise generation.

8. Prevent gas from entering the centrifugal pump: If the discharge valve is not closed before the centrifugal pump is started, gas may enter the centrifugal pump and affect the normal operation of the centrifugal pump. Closing the discharge valve can prevent gas from entering, thus ensuring the normal operation of the centrifugal pump.

9. Protect the pipeline system: Closing the discharge valve can protect the pipeline system and prevent damage to the pipeline system due to excessive flow or excessive pressure.

10. Improve the working efficiency of the centrifugal pump: Before starting the centrifugal pump, closing the discharge valve can improve the working efficiency of the centrifugal pump, because the centrifugal pump can reach the required head and flow faster when started at a smaller flow rate.

What Will Happen If Discharge Valve Of Centrifugal Pump Is Closed

If the discharge valve of the centrifugal pump is not closed before starting, it may cause the centrifugal pump to have excessive starting current, reverse flow, excessive pressure in the pipeline system, damage to mechanical parts, unstable flow and lift, pump vibration, and noise, motor overload, Problems such as water hammer, reduced pump efficiency and accelerated seal wear. This shows how important it is to close the discharge valve before starting the centrifugal pump. Next, we will explain one by one the problems that may arise.

1. Excessive starting current: The centrifugal pump must overcome the medium and internal friction resistance when starting. If the discharge valve is not closed, the starting current of the centrifugal pump will be too large, which will burn out the motor.

2. Reverse flow: After the centrifugal pump is started, if the discharge valve is not closed, the centrifugal pump will run in reverse, sending the water in the centrifugal pump back to the original pipeline. Such a flow direction is opposite to the original flow direction, which will cause damage to the pipe. Pipe linings, anti-corrosion coatings, elbows, etc. are damaged, causing pipe rupture.

3. Excessive pressure in the pipeline system: When the centrifugal pump is started, if the discharge valve is not closed, the driving force generated by the impeller of the centrifugal pump will cause the medium to flow rapidly, thereby generating a pressure gradient, increasing the load pressure of the pipeline and pumping station, and increasing The operating burden of centrifugal pumps adversely affects the centrifugal pump and piping system.

4. Damage to mechanical components: When the centrifugal pump is started under no-load or low-load conditions if the discharge valve is not closed, excessive axial thrust may be generated, causing damage to components such as mechanical seals.

5. Unstable flow and lift: When the centrifugal pump is started, if the discharge valve is not closed, the flow and lift will be unstable, affecting the normal operation of the centrifugal pump.

6. Vibration and noise of the centrifugal pump: When the centrifugal pump is started, if the discharge valve is not closed, the centrifugal pump will be in a low-load or no-load state, causing the vibration and noise of the centrifugal pump to increase. Long-term operation will cause damage to the centrifugal pump and pipelines.

7. Motor overload: If the discharge valve is not closed when the centrifugal pump is started, the motor may be overloaded, causing the motor to heat up or even burn out.

8. Water hammer: When the centrifugal pump suddenly stops pumping, if the discharge valve is not closed, a water hammer may occur, causing impact and damage to the pipeline and centrifugal pump equipment.

9. The working efficiency of the centrifugal pump decreases: When the centrifugal pump is started if the discharge valve is not closed, the working efficiency of the centrifugal pump may decrease, because the discharge valve is not closed, which will cause flow loss inside the centrifugal pump and reduce the working efficiency of the centrifugal pump.

10. Accelerated seal wear: If the discharge valve is not closed when the centrifugal pump is started, the mechanical seal or packing seal may accelerate wear, causing seal leakage and damage.

If you want to know more why discharge valve is closed in centrifugal pump, please view this video. Video source: https://www.youtube.com/watch?v=p00BM-QOrEc

Centrifugal Pump Be Started Without Closing Discharge Valve?

In actual operation, if the following two situations occur, the discharge valve does not need to be closed when the centrifugal pump is started.

1. Working conditions: In the case of low flow and high head, the centrifugal pump does not need to close the discharge valve when starting. However, this cannot be done when the flow rate is high and the head is low, otherwise, it will cause the centrifugal pump to overload and the motor to overheat.

2. Type of discharge valve: Different types of discharge valves (such as throttle valve, globe valve, etc.) have different effects on the starting of the centrifugal pump. In some special cases, if the centrifugal pump is started without closing the discharge valve, it may cause the pressure on one side of the centrifugal pump to be too high, causing the cover of the centrifugal pump to deform or the bearings of the centrifugal pump.

It can be seen that whether the discharge valve needs to be closed before starting the centrifugal pump must be analyzed based on the actual working conditions and the type of discharge valve. We should follow operating procedures during actual operation to avoid equipment damage.