1、You are in restricted area and need password. Please Contact us to obtain documents.

2、PasswordIf you have any questions about quotation or cooperation, please feel free to send us inquiry. Inquiry us

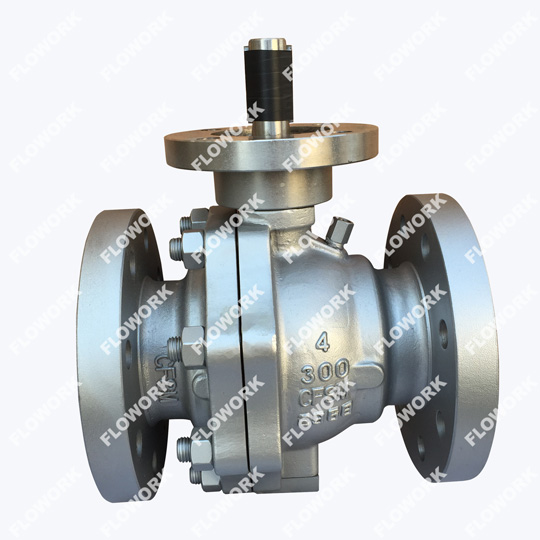

| Size: | 2"-56" |

| Pressure: | 150LB-2500LB |

| Body Material: | CF8, CF8M, CF3, CF3M, CD3MNWCuN, CW2M, Monel, CN7M, 20#Alloys, 4A, 5A, etc. |

| Seal Material: | PEEK, RPTFE, PTFE, DEVLON, HNBR, NYLON, AFLAS, STELLITE,etc. |

| Connection Type: | Flanged, Butt Welded, Socket Welded, NPT |

| Operation: | Hand lever, gear operated, pneumatic, motorized |

| Face to Face Dimension: | ASME B16.10 |

| Flange End Dimension: | ASME B16.5 |

| Butt Welded Dimension: | ASME B16.25 |

| Design and Manufacture: | API 6D |

| Test Standard: | API 598, API 607, API 6FA, ISO 15848-1-2 |

Structure type: one-piece, two-piece and three-piece

Stainless steel material, such as CF8, CF8M, CF3, CF8C, CF3M, F316, F304, F347, etc.

With reliable sealing performance and corrosion resistance

End connection type: flanged, bw ends, sw ends, npt ends, fully weld ends

Suitable for low temperature usage due to the stainless steel material characteristics

Fluid resistance is small; no flow resistance especially for full bore type ball valves

Operation: lever, worm, pneumatic actuator, electric actuator, etc.

To control actuated ball valves, you will need to use a control device such as a switch, a timer, or a programmable logic controller (PLC). The control device will send a signal to the actuator, which will then rotate the ball valve to the desired position. The actuator can be electric, pneumatic, or hydraulic, depending on the application. It is important to ensure that the control device and actuator are compatible and properly installed for safe and efficient operation, ball valve manufacture.

To know if a ball valve is in the off position, you can look at the handle or lever attached to the valve. If the handle is perpendicular to the pipe, it means the valve is in the closed or off position. If the handle is parallel to the pipe, it means the valve is in the open or on position. Some ball valves may also have markings on the handle or body indicating the open and closed positions, gate valve manufacture.

It is generally recommended to disassemble a ball valve prior to soldering. This is because the high temperatures involved in soldering can damage the valve's internal components, such as the seals and seats. By disassembling the valve, you can protect these components and ensure that the valve operates properly after soldering. However, if the valve is specifically designed for soldering, it may not need to be disassembled. It is always best to consult the manufacturer's instructions or seek the advice of a professional plumber to determine the best course of action, bronze valve.

Ball valve CV refers to the flow capacity of a ball valve, which is a measure of the amount of fluid that can pass through the valve in a given period of time, high temperature gate valves. It is expressed in units of gallons per minute (GPM) of water at a specified pressure drop (usually 1 psi). The CV value is determined by the size of the valve, the shape of the ball, and the position of the ball within the valve. A higher CV value indicates a larger flow capacity, while a lower CV value indicates a smaller flow capacity, api 6d ball valve.

Ball valves with drains are typically used in applications where it is necessary to drain the system or equipment being controlled by the valve, carbon steel gate valves. The drain allows for easy removal of any residual fluid or debris that may be present in the system, which can help to prevent damage or contamination. Some common applications for ball valves with drains include water treatment systems, chemical processing plants, and HVAC systems. Additionally, ball valves with drains are often used in applications where frequent maintenance or cleaning is required, as the drain allows for easy access to the interior of the valve, forged ball valve.

Send us a message if you have any questions or request a quote.

A reply from our experts within 24 hours

The latest detailed product catalugue

One-stop service for your project